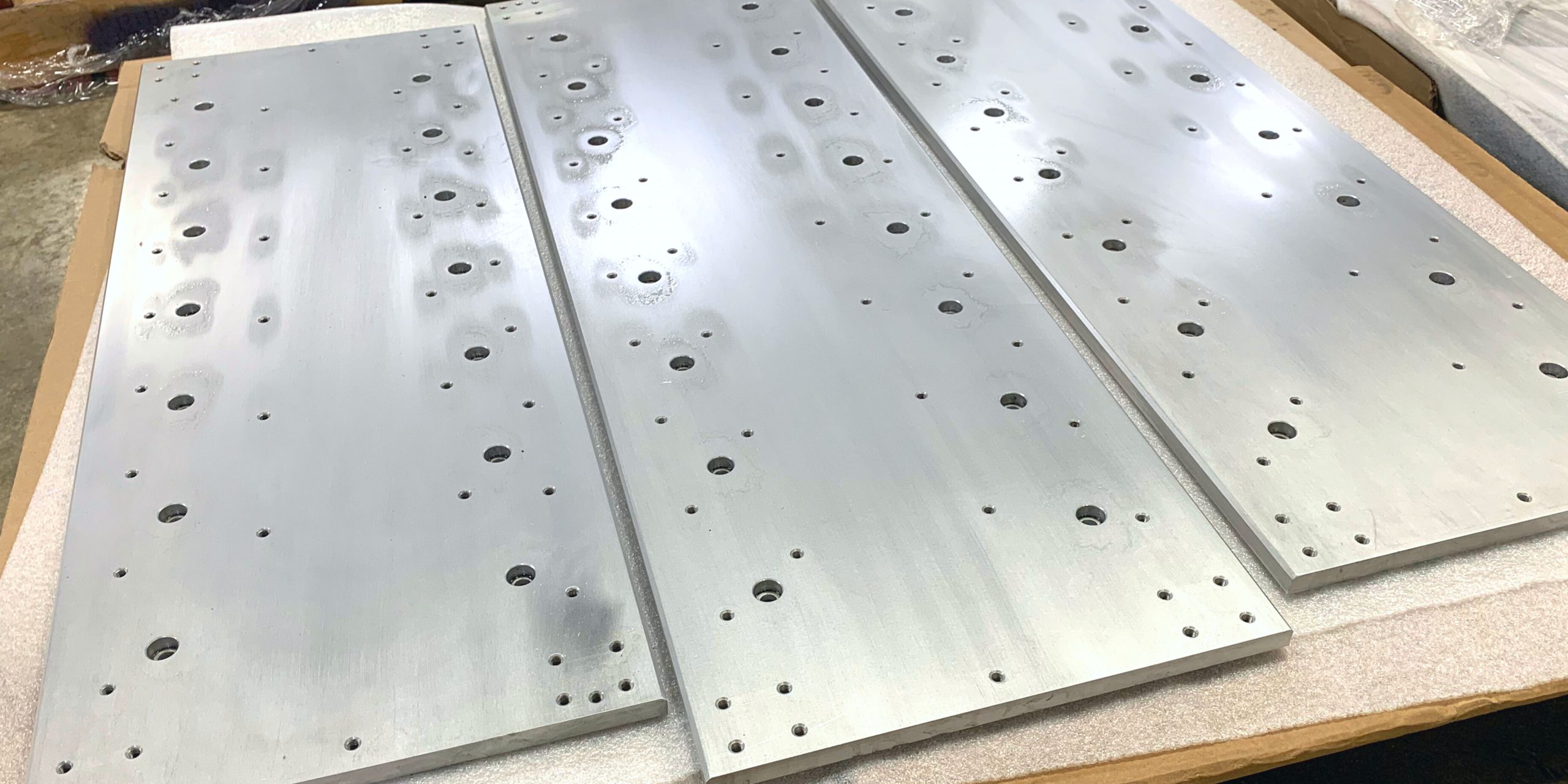

EQUIPMENT / FACILITIES

What We Use To Take You

FROM “PRINT TO PART”

Our facility stretches over 27,000 square feet and houses over 90 machines including Blanchards, Surface Grinders, Jig Grinders, OD/ID Grinders, Centerless Grinders, Belt Grinders, Double Disc Grinders, Lapping Services, Honing Services, CNC Machines, and Inspection Equipment.

We also offer secondary operations such as heat treating, steel stress relieving, black oxide, paint, welding, and more.

One of our core values is continuous improvement. We believe in ongoing investment back into our equipment and facilities so we can better serve our customers’ needs. As we continue to grow, this list of machines will continue to grow as well.

BLANCHARD GRINDERS

- 2 – 84″ BLANCHARDS

- 1 – 60″ BLANCHARD

- 1 – 48″ BLANCHARD

- 2 – 42″ BLANCHARDS

- 3 – 36″ BLANCHARDS

- 2 – 16” BLANCHARDS

- 2 – MULTI-HEAD BLANCHARDS

SURFACE GRINDERS

- 1 – GRAND RAPIDS – 32” x 98”

- 2 – THOMPSON -17” x 60”

- 1 – THOMPSON – 24″ x 48”

- 1 – MATTISON – 12” x 36″

- 2 – GRAND RAPIDS – 12″ x 30”

- 1 – THOMPSON – 8″ x 24”

- 2 – REID- 6” x 18”

- 1 – NICCO – 14” x 26”

JIG GRINDERS

- 2 – #3 MOORE JIG GRINDERS

- 1 – #2 MOORE JIG GRINDER

- 1 – SPRINGFIELD VERTICAL GRINDER 30” CAPACITY

OD / ID GRINDERS

- 2 – CNC OKUMA OD/ID GRINDERS

- 1 – 12″ x 48″ O.D. CIN. GRINDER

- 2 – 14″ x 36″ CIN. UNIVERSALS

- 2 – 10″ x 24″ CIN. UNIVERSALS

- 1 – 4″ × 18″ CIN. GRINDER

- 3 – #271 HEALD I.D. GRINDERS

- 1 – 10” x 30″ PARKER MAJESTIC

CENTERLESS GRINDERS

- 3 – CINCINNATI NO. 2 OM

BELT GRINDERS

- 2 – 36″ TIME SAVER WET BELT GRINDERS

DOUBLE DISC GRINDERS

- 1 – DH6-30″ BESLY ROTARY

- 2 – DH6-30″ BESLY THRUFEED

- 1 – 30″ GARDNER ROTARY

- 1 – 23” GARDNER THRUFEED

HONING SERVICES

- 1 – MDB – 165O AUTOMATIC SUNNEN HONE

- 1 – MBB – 166O SUNNEN HONE

MACHINING

- 2 – 20″ × 40″ CNC HAAS VF-3 MACH CENTER

- 1 – CNC HAAS EC300 (HORIZONTAL)

- 1 – CNC HAAS EC500 (HORIZONTAL)

- 1 – CNC HAAS SL30 LATHE

- 1 – CNC HAAS SL40 LATHE

- 1 – CNC HAAS DS30Y LATHE

- 2 – CLAUSING-COLCHESTER 15″ ENGINE LATHES

- 3 – BRIDGEPORT MILLS

INSPECTION EQUIPMENT

- FULL CMM INSPECTION CAPABILITIES

- MITUTOYO HEIGHTOMATIC 450

- KODAK COMPARATORS

- FULL RANGE OF STD INSPECTION EQUIP

- SURFACE PLATES THROUGH 48″ x 98”

SECONDARY OPERATIONS

- GROUND BURNOUTS SUPPLIED

- TUMBLING / DEBURRING

- HEAT TREATING / STRESS RELIEVING

- CHROMING

- PRODUCTION SAWING

- KNIFE GRINDING

- 4 & 6 – SIDED GRINDING

- ANGLE / CONTOUR GRINDING

- SAND BLASTING

- BELT SANDING

- BLACK OXIDE

- PAINT

- WELDING

- ANODIZE

- AND MORE…